CAP COMPRESSION MOLDING MACHINE

Jobo India brings to you one of the most advanced Compression Molding Machines in the Cap manufacturing industry. Jobo India is the trusted Indian partner of Jobo Machinery, a global leader operating in over 60 countries. Cap Compression Molding Machine is a modern machine used to make plastic bottle caps. This method uses less energy and produces less raw-material waste compared to old methods like injection molding. The Cap Compression Molding Machine is ideal for making caps for water bottles, soft drinks, Juice, Pharma, Cosmetics and other industries. If you want strong and lightweight caps, then Cap Compression Molding Machine is the right choice for you as it helps save cost and improve Cap quality.

HOW THE CAP COMPRESSION MOLDING

MACHINE WORKS?

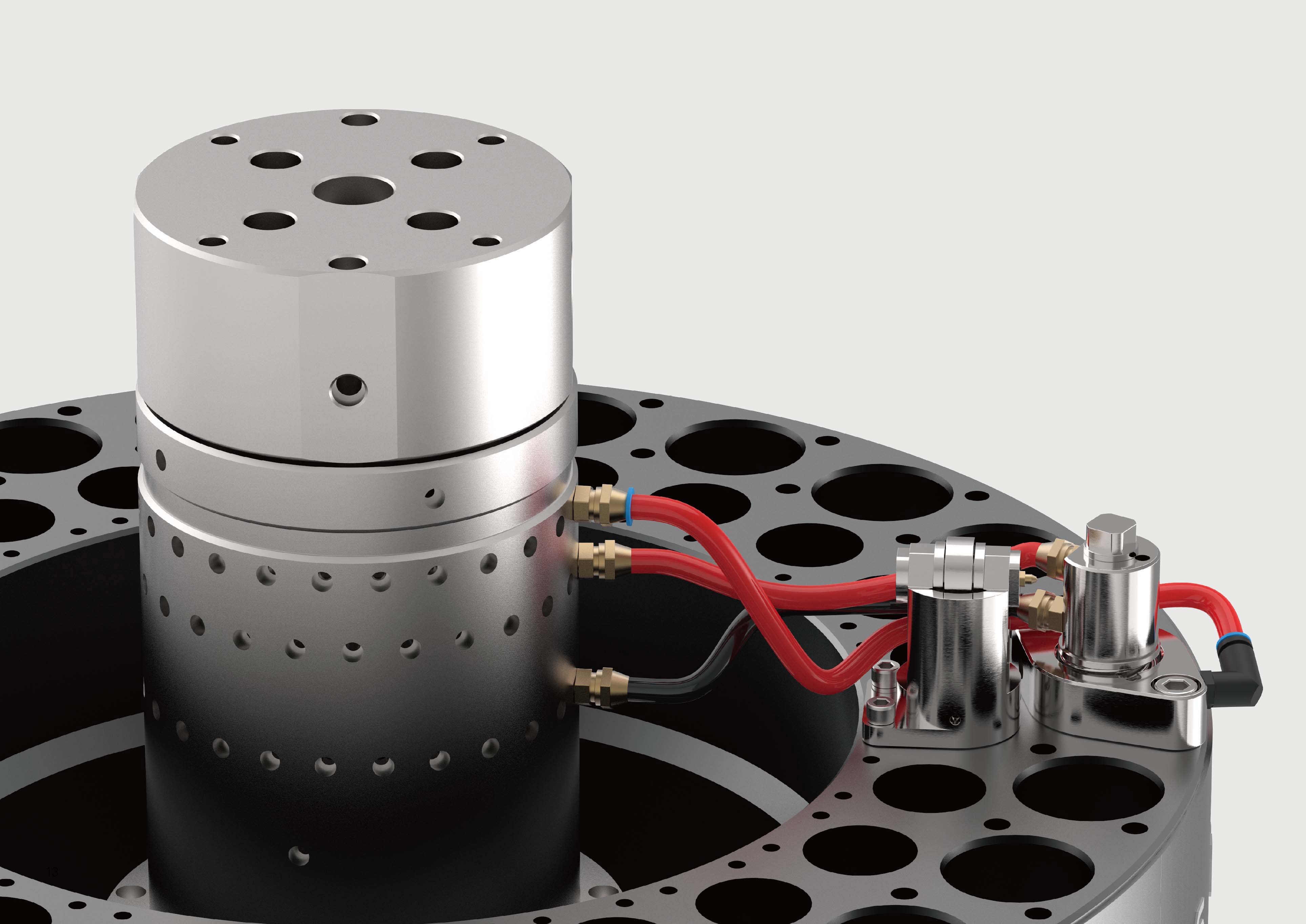

The Plastic granules are heated to melt into semi liquid form and then take up unit cutter lifts the material from the tip of extruder (the parameters are set to cut the pellets into specific weight) and dropped into the Cavity. The Mold cavity is then compressed by a Hydraulic rotary compression system, which forms the pellets into the desired shape of the cap. The cap is then cooled and ejected from the Cap Compression Molding Machine .This process is fast, efficient, and eliminates the risk of wasted material, making it a highly sustainable option for cap production.